Cnc Software

This is a totally integrated solution and recommended if you need CAD and CAM capabilities! The Process to get an actual physical part created on a CNC machine is designing, providing machining operations to the design, then putting that into the control program of the CNC machine so the machine can cut or fabricate the part. This software takes care of the first two: the design and applying the machining operations. CAD software is generally in the thousands, and CAM requires additional dollars, so why not just get an integrated solution like BobCAD! Before I get farther in the software toolchain for the Windows operating system, I will cover the primary software for Linux.

Get a 2D & 3D CAD-CAM Demo - CAD/CAM(Computer Aided Design - Computer Aided Manufacturing) Software for CNC Machining: CNC Milling, Turning, Routing and.

If you are partial to Linux, or you think Linux is some kind of animal and don't know what the heck I'm talking about, this alternative software toolchain may interest you. Devil May Cry 5 Download Full Rip Music Download there. This tutorial would not be complete without covering the open source side of CNC computer controls.

You may find that using (the CNC control that runs under Linux) may be a bit more problematic than Mach3 since there is limited CAD (design software) out there for the Linux operating system. I said, operating system. I you don't know already, Linux is an operating system about as old as the Windows operating system.

Excellent results can come from a small CNC router, but don’t forget the software! CNC tools, whatever their flavor, can greatly enhance your “making” or DIY ability. My current tool of choice is a CNC router. Being familiar with a manual milling machine, the concept seemed similar, and the price of these is quite reasonable when compared to some other tools. As t, my machine is a, but there are certainly other options to visit like this noted recently. Although any number of CNC router models look great in videos and pictures, rest assured that even the best machines require some patience to get one running satisfactorily.

Setting up the machine can be a challenge, as well as figuring out what your machine is capable of, but one thing that might slip peoples’ minds is the software involved. Read on to find out all you need to know the basics of what goes on behind the scenes to “magically” produce interesting parts. With a CNC router run by a computer (as opposed to a dedicated controller), you have three parts in your tool chain: Computer aided design (CAD), computer aided manufacturing (CAM), and a machine controller package. There are free and paid versions of each of these. Design Your Part Design and my idea to shrink the knife block to make a The first step is to draw your part.

To generate my part drawings, I’ve experimented with, a vector graphics editor, and, which is more or less free AutoCAD. Inkscape is a really cool program for generating more artistic pieces, like that I cut a while ago. If you want to do something more dimensionally-driven, my preferred tool is Draftsight. I’m very familiar with AutoCAD, and it’s available for Linux, Mac and Windows.

If you want to get into 3D design, Sketchup seems to be more-or less the standard for casual makers/hackers/etc. Perhaps I’ve been spoiled or brainwashed by quite a few years of working with, and to a much smaller extent, because I found Sketchup frustrating. I find Pro/E (now Creo) frustrating as well at times, but I’m paid for that frustration. Regardless of what style or design program you choose, if you’re not familiar with the format, plan to spend a decent amount of time figuring out how to generate your parts.

Generate Gcode Meshcam screen, unlike what some mid 90’s rappers would have you believe, stands for General Code, and is what directly controls a CNC machine. You can write G-Code by hand, and for very simple circles or lines, this might be practical. For most circumstances, however, G-Code is much easier to produce using a CAM program to translate your CAD model into this format.

I’ve tried out several packages, and all have their advantages and disadvantages: • – Free, great for art generated on Inkscape. Somewhat limited in capability, and the documentation may take a little time to figure out. • – Inexpensive at $35, and it has a good-looking interface. More of a 2D environment, and you can draw your parts on this program if you like.

• – Reasonably priced at $149, with a very good free trial period. I primarily use this CAM program. • – Really excellent looking user interface, and it has some neat features. Along with this polish, it is more expensive than some at $250. It’s geared more toward 3D users, so it wasn’t a great fit for my Draftsight-centric CAD style. • – If you’re a programmer (or pretend to be), it’s possible that you could write your own Gcode generating script.

I’ve linked to a post on my “pixel machining” Python routine if you’d like to see an example. Along with actually learning the software, you’ll need to consider what kind of speed your machine can actually handle, and what to do so you don’t “crash” your machine.

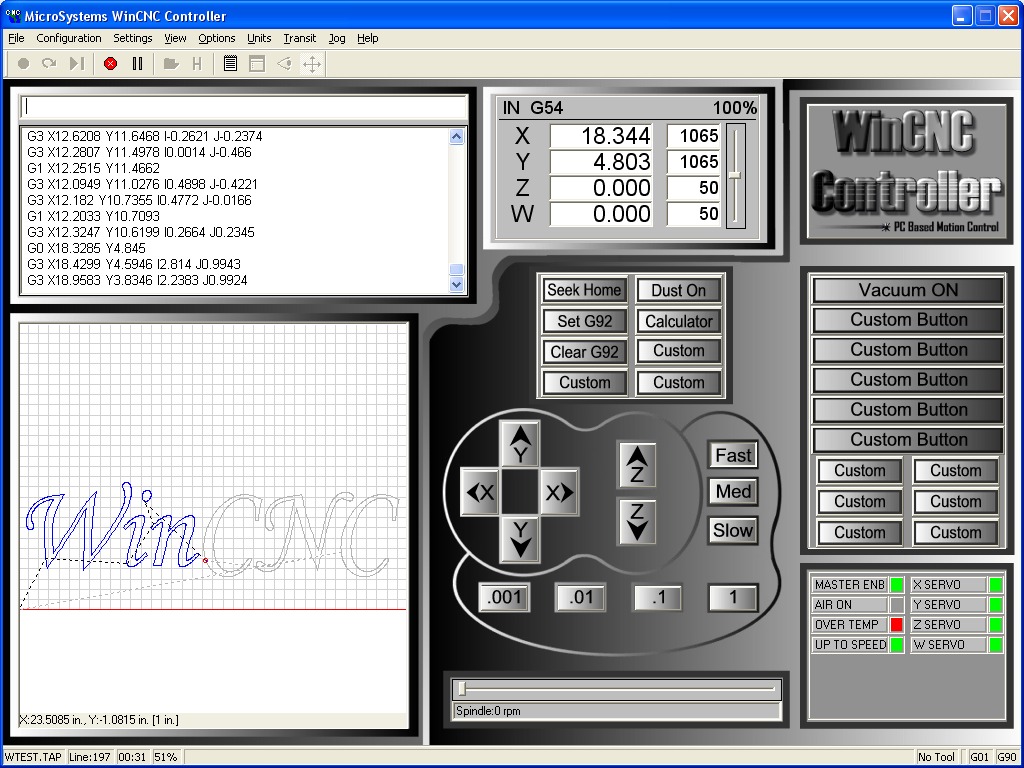

Your CAM program is where you set up your feeds, speeds, depth of cut, and other parameters. Control Your Router Mach3 to control your router Once your CAM program spits out possibly several thousand lines of G-Code, your machine control software is what gets everything moving. I use, which seems to be a common program for hobby machine control.

Like everything else, it has a learning curve, but overall I’m quite happy with how it performs. One weakness I ran into with this (and that is probably true of other programs) is that you need an actual parallel port for it to work properly (not a USB-parallel adapter), and it’s not supposed to be run on a notebook because of possible power management issues.

I’m sure there are workarounds, but in the interest of saving time, it might be a good idea to just dust off (or purchase) an old computer to run it on. It will run comfortably on slightly antiquated machines, so for $150 or so, you can have a computer that will run your router. Another option would be. When I started leaning CNC, I was almost entirely unfamiliar with Linux. The challenge of leaning a new OS along with a new router seemed like too steep of a learning curve, so I haven’t tried this option. As I use Ubuntu quite a bit now, I might take a different track today.

If you have worked extensively with LinuxCNC please share you experiences by leaving a comment below. To wrap things up, here’s two CNC videos that I’ve made. The first is me engraving a Tiger Paw, whereas the second video is a tutorial I did on how to engrave a logo using Inkscape. A CNC machine is a great addition to any shop, but as I hope I’ve pointed out here, not without its challenges! Please note that separate from this post, I have received special pricing and/or samples in order to try out products from the companies representative of Zen Toolworks, Mach3, ESTLcam, and MeshCAM.

Jeremy Cook is a Mechanical Engineer with a degree from Clemson University, and works in manufacturing and process automation. Additionally, Jeremy is an avid maker and former Hackaday staff writer. When he’s not at work or in the garage, you can find him on, his projects blog, or on his photography-related blog. Posted in,, Tagged,,,,, Post navigation. Traditionally a mill would move the workpiece, allowing the spindle to stay still, whereas the spindle on a router moves and the workpiece stays still.

Also, a mill is generally meant for metal cutting, where a router is meant for wood/plastic. The effect is similar, and there’s definitely some shared capabilities, but it’s a different means to an end. At least that’s my thinking on it.

As macona alluded to, the line gets blurred a bit with modern CNC machine tools. Even my little ZTW hobby router is kind of a hybrid; the bed moves in the Y direction, where the spindle moves in the X and Z direction. In addition, there are various designs for routers. Some have designs where the work piece stays stationary and the router moves on a gantry. Others the work piece moves on a table and the router head stays stationary (less popular).

Both mills and routers can cut many materials from wood, metals, plastics, etc. With the proper bits though cutting harder metals is very difficult for a router head. Routers might bewell, ran by actual wood routers or some people have upgraded and opted to put spindles on their machine (nearly identical setup but the motor is designed to run for long periods of time without damage. Some are even liquid cooled.) In short, to clarify from what others are saying the type of material or how it cuts the material isn’t what differentiates between router and mill. It is the setup (mainly) and their capabilities. Router – flat stock lying down (unless we are talking 5 Access routers – then think automated sculpture carving capabilities) and mill – turning parts. @John: Perhaps, CNC router is just for wood, while CNC mill could cut any materials?

Inkscape is great, but there is some learning curve if you want to design in it. If you have just a black-and-white image, and need to cut out the shape, Inkscape will easily generate smooth g-code for you, LinuxCNC is great and much easier to use than Mach3. Also, LinuxCNC/EMC2 can mill bitmaps (for example, png files) using pixel brightness as a Z axis. Also, there is Heeks CNC, which produces G code. It has limitations, and occasionally crashes, but still quite usable. I am a hobby CNC explorer. Yes, there is a learning curve, but half the fun is learning, so I enjoy, rather than despise this part.

My CAD/CAM solution is BobCAD. It’s tricky to learn, but does the job for both CAD and CAM. I bought a used version from eBay and it works fine. It has both 2D and 3D options for either engraving or full 3D cutting. Mach3 is ok, but my PC crashes every once in a while, even after eliminating most of the causes. My CNC machines are modified Sieg (3D) and Enco (2D) knee mills.

You could buy something form Zenbot to Tormach, depending upon your needs and your budget. Unless you are into the engineering aspect, I would recommend buying something off-the-shelf, or something from Craigslist that meets your buget, then upgrade or build one your self later on. Tackling on the CAD, CAM, integration, PC, CNC building all at once can be daunting. This hobby can be handy: I just carved out of aluminum some quadcopter legs that are no longer made.

Meine Tierarztpraxis Einsatz Auf Dem Land there. Hackaday rocks. Anyone considering using Mach3 should get some of the story straight from the horse’s mouth so to speak. Search for “Mach3 Plug-In Writers Bible by Art Fenerty” to see what a load of horse pucky that stuff really is. Finding out exactly what happened to Mr. Art Fenerty might be an interesting exercise too.

Some say he retired, others say he disappeared like a thief in the night. His departure was a rather abrupt thing, that’s for sure. Something’s rotten in all of this. Anyhow, also be aware that both Mach3, and LinuxCNC are based off the same NIST code base. Just one guy went one way with it, and another team went another. Now if after all of this you’re still seriously considering using an application on Windows for mission critical machine control you should seek professional psychological help.

Because you’re nuts! Mach3’s problem is not that it runs on Windows. The problem is – alternative free software (EMC2) is much easier to configure and use. I have got Mach3 on a CD that came with motor controller. I gave up with it despite the instructions and screenshots that came with the controller.

Then I installed LinuxCNC with EMC2, configured it and started using with no problems. I disagree about Windows. I do control multi-million-dollars hardware from Windows 7 PC at work, and it runs for weeks with no problems. Yes, Windows 95 was unreliable, but that was long time ago. Don’t forget the realtime aspect of it.

I’m not all that familiar with Mach3, but Windows and realtime aren’t the best friends. I think people have worked some expensive things out for industrial solutions which offloads stuff onto a dedicated controller with some brains. But for the average person with Mach3 on a desktop I think the lack of realtime is a major disadvantage compared to LinuxCNC. In that sense, the problem IS that it runs on Windows which does not have comparable realtime add-ons like RTAI, Xenomai or even RT-PREEMPT.

Might be running an embedded version of Windows. Same code-base as ordinary Windows for desktops and laptops but has a system that does extreme customization of the install so it has only the components absolutely required for the system it will be used on.

XP Embedded is still very commonly used, though Microsoft did an update in 2009 which was still pretty much XP based before they released the next version which is (IIRC) Windows 7 based. AFAIK, the only time Windows embedded has been used on a consumer PC was Dell Media Direct (through version 3.5) on some of their laptops.

Through version 2.0 it was installed in Host Protected Area though it could also be installed in a normal hidden partition on non-original equipment hard drives. DMD 3.0 through 3.5 used the reinstall partition scheme of earlier versions by default. After 3.5, Dell abandoned the special partition and Windows Embedded, making Media Direct simply a multimedia program running in normal Windows. Windows Embedded allowed for a faster loading version of Windows and the ability to run normal Windows multimedia software, unlike the similar scheme used by Hewlett Packard that ran a custom build of Linux for their fast booting CD and DVD playing mode.

On a CNC machine it would be possible to create a special install of Windows embedded that has no extra baggage, and has special drivers for realtime control of machine control hardware. Mach 3 has its own parallel port driver, which I assume does some tricks like that. Contrary to popular belief, it is possible to do anything with the parallel port that was possible with Windows 9x or DOS.

Mustek was one of the first companies to prove it when they released Windows 2000 (and later XP) drivers for most of the parallel port scanners they’d made, including many discontinued models. Meanwhile, UMAX dropped support for all their parallel port scanners, claiming it was “impossible” to use a parallel port for scanning in Windows 2000 and XP. A while after Mustek went and did the “impossible”, UMAX released 2000 and XP drivers for some of their parallel port scanners. Claiming something is “impossible” to do in Windows just means you either can’t figure out how to do it or just don’t want to try. Your question is a bit tricky to answer because LinuxCNC is an open source project. Being such there is no single cut and dried, here you go, this is the latest code you can have answer really. You can build the RTAI kernel extensions on a very up to date kernel version and run that with the LinuxCNC code.

Admittedly the LinuxCNC ISO image is pretty stale today. Personally I don’t use it. I did my last build on Debian Squeeze, but I was looking for something supported, not necessarily the latest, or the greatest, I could have. Plus Ubuntu just makes me want to puke, but that is another matter entirely. The strength of free open source is the freedom it gives you. I take full advantage of that too with LinuxCNC. I almost got LinuxCNC to work on Gentoo, but managing to do that is a real bitch.

Knowing what I know today if I gave it another try I could probably do it. I had one obscure problem that I’ve since found the answer to that stopped me the last time. I was getting some pretty insane latency scores on Gentoo. Like 1750 nanoseconds. I was only using an old X2 AMD CPU too. Another +1 for LinuxCNC. In response to “will it run [insert thing here]” the answer is yes it will run anything, including complex articulations like delta robots, SCARAs and Stewart platforms, with caveats.

The onus is placed on the user to learn the system and then reconfigure the INI and HAL (and perhaps ClassicLadder if that’s your chosen route) for their application. LinuxCNC is an insanely robust and underutilized platform, IMHO, and its potential is completely wasted by the fact that what little documentation does exist is arcane in the extreme. That said, I bothered to learn Linux just to be able to use LinuxCNC effectively Check my webpage for some example HAL and INI files. It is as simple as getting the ISO image and booting it. You don’t even need to install LinuxCNC in order to run it.

LinuxCNC runs live. You can plug LinuxCNC in and go. The best LinuxCNC installs don’t use hard drives at all really. Because shop environments can be harsh many choose to run off a CF card. But to run a live session you can use a USB flash drive. Oddly I can’t find good instructions on the net for how to do this. If it were me I’d download the ISO then use unetbootin to write the image to the flash drive.

The LinuxCNC ISO is based on Ubuntu, but it isn’t exactly Ubuntu so generic Ubuntu instructions wouldn’t quite work. Choose the ISO image option in unetbootin. I just checked and LinuxCNC isn’t a menu item. Some LinuxCNC users and devs hang out in #linuxcnc on chat.freenode.net You can ask them if you get real stuck. I’ve heard P4s aren’t particularly good at real time latency.

I have one but I never benchmarked it. For a little while I was using a P3, and it is kind of crappy. I run about 18,500ns with it. Now I have a 2.5GHz AMD X2 and it can score about 7,500ns. Which isn’t too shabby considering that I only paid $5 for it. If I were to buy new I’d go with an Intel Atom.

They’re the best bang for the buck. Latency scores are a funny thing.

The highest performing PCs aren’t always the lowest latency machines. Real time latency isn’t something computer users generally have any grasp of. It isn’t a spec Tom’s hardware is really publishing. Here’s a chart that needs to be taken with a grain of salt because many there don’t know how to configure the software optimally. Knowing what one is doing can make a lot of difference.

But it may give some an idea of what hardware can do what. The second time column is the important one for steppers. Lower is better of course. I have mini mill that came w/ a presetup computer w/ mach3 that I used for about 2 months. I then tried out linuxcnc and have been using it for maybe 4months. Since I used both pieces of software let me start this writeup with a bulleted list. Mach3: * Nice well written plugins (called wizards) for simple functions, but most cost money.

Oh I guess I should make a quick blurb on hardware, even tho this is a software post. You actually DON’T need a fast modern pc to do all the stuff needed to run your machine.

It will help for the CAD stuff, as CAD packages can really work out a computer, but for the actual execution of the G-code almost any speed processor will do, even a PII I have heard of as working fine. IT is not PC speed that matters, but “latency” which is a very specific way of measuring speed.

It is VERY HARD/IMPOSSIBLE to predict the latency of a computer based on its specs. The good news is you can check your latency using a LiveCD of Ubuntu with linuxCNC pre-installed on it. Plenty of info on that on the web for you. You do however need a real parallel port on your computer. The easiest way however is to ask online/search the forums for what computers other people are using already and just copy what they ahve. There was an Atom mobo/cpu combo that is no longermade but folks still have in stock that was a popular cheap choice, again the info is out there. A big tip I got is get a graphics card, ANY graphics card adn your latency may improve massivly, so my 12+ year old PC is now happily running my mill.

Another option is beagleboard. I would have bought one immediatly if I had known waht it was back when I bought 2 raspis to learn on.(remember I am a mechanical guy, pcs are tools to me, not toys) Since CNC stuff is mostly industrial mfring up untill recently, hardware moves very slowly in that world so parallel ports are still god, lots of stuff runs thru them, or purpose built PCI/PCIe cards (check out mesa, but even having used CNC stuff for a while now, browsing thier site I still can’t make heads or tails of what I am looking at) so it is very easy to expand it seems. HOWEVER don’t get tricked like I did, I thought “hey my repraps use arduinos, i bet in the future I could ditch the PC and just have an arduino and raspi hidden udnder my workbench” but nope. I guess CNC machinging utilizes the full power of g-code a bit more than a reprap currently does, and will stress a raspi to its limits and an arduino just isn’t up for it.

But with most of you nerds back room full of at least 20 machines “too old to do anything useful” why worry, you probably already have the box you need for a CNC. Save that money and speand it on a touch screen monitor. It troubles me that the writer of the article doesn’t understand why a parallel port is so critical (or some sort of real hardware connectionlike a Mesa card). It’s latency!!!!!!

You can’t run a real time process through USB. Let alone through a PP-to-USB adapter. This tells me the writer hasn’t build one of these machine before and doesn’t understand the underlying concepts. I have used MeshCAM. At first, the interface seemed great. After messing with it for a while, I found it lacking features and with bugs. You end up editing a lot of gcode before it’s really usable.

But it’s only $250 and I am need of features of the $1,000-2000 CAM packages. So, it’s a different set of expectations and resulting features. LinuxCNC is THE way to go. I have one LinuxCNC 3 axis mill. I am just getting started on a larger mill.

The basic configs are easy to setup, but once you get into modifications and customizations, the learning curve becomes very steep. But LinuxCNC is so insanely powerful. I believe some OEMs use LinuxCNC and just dress up the interface. I started out 3 years ago on a chinese cnc router with very crappy software to run it.

You’d lose your origin all the time and had no way to use the machine homing switches correctly. I quickly converted that over to linuxCNC (10.04 back then) which gives a much more reliable control. Too bad the axis interface is a little complicated, esp.

Two buttons next to each other, one (home) only used when initialising the machine, the other (touch-off) doing conceptually nearly the same, but for each workpiece. It is quite easy for new users to press the wrong button, ignore the warning and ruin their workpiece. For gcode I am moderately happy with deskproto.

Very well suited to 3D milling, but a lot less nice for 2.5D, which you tend to do a lot with a 130x245x9 machine To everyone swearing by mach3: it is a piece of crap compared to linuxCNC. Your experience with keys on linuxcnc sounds exactly like the sort of thing you should be able to customize in the package. Changing keybindings should be pretty basic. That said, you are lucky. I am trapped in proprietary land with a Next Wave Automation cnc shark.

I would love to customize basic features – the software works well but the UI is very crude. The usb control box only works with their very limited control software. And the control software requires a registration key despite the fact that it only works with their hardware. They say that is to protect against stolen machines being used, but it makes no sense. In years to come I fully expect the machine will be a brick due to no registration keys. They are unwilling to allow mach3 or any alternatives.

The user must be controlled! About three years ago I pulled a computer out of the dumpster to fiddle around with it. It had two problems. 1: One of the cooling fan mounts was broke.

The addition of a zip tie and that problem was solved. The CD drive was stuck closed which was quickly resolved with a paper clip. It had a cd game in it to boot. The next thing I did was to install Windows 7 32 bit. Once I had my bluuMax setup, I installed Mach3 and ran some tests. Once I had the wiring and everything properly seated, Mach3 worked just fine. Then I installed LinuxCNC in a dual boot setup.

LinuxCNC runs just fine. Based on the problems people posted here, I must have lucked out with my setup. I am running my desktop CNC thingie (can’t call it neither a mill nor router) on Sanguinololu + grbl. After some fiddling to allow non-standard pin assignments in grbl (see: ), it does work fine. However, standalone operation is kind of a moot point- you still need a computer to send g-code to grbl (and it’s quite easy to interrupt communication with controller, e.g.

By accidentaly rebooting the box to install the latest kernel a few hours into a milling job). I’m looking forward to controllers like smoothieboard/4pi- totally autonomous after you’ve started the milling job (send the file over by USB/Ethernet and it’s saved on SD card).

But it’s an order of magnitude more expensive and not rock solid at this point. As long as the computer in the shop supports a flash drive you can do that easily. If the two computers are on a network you can do it by sharing a folder from the old computer and copying the files over to it. I just looked at the website and felt like I was going to hit my head on the banner at the top of the page and that is not talking about the text that is so close to the bottom of the banner and runs up under it that I feel like they are hiding something from me.

Then there is this annoying support link that is positioned in a place were it is right on top of text and this again made me feel like they were hiding something. Are you using BobCad as the controller?

From the above post, I am assuming that if you put your single license on your laptop, you will need to use your laptop as the controller unless you install LinuxCNC on it, then it won’t matter. This is the biggest problem with single computer apps that have multiple functions.

One computer is better as a controller while the other is better for processing the CAD files and generating the g-code. The shop setup may not be as comfortable as the setup you have in your office. You could try and install BobCad to an external drive such as you would do with PortableApps. Then you can move the drive back and forth. Design on your laptop, move the drive to the shop and run the CNC. It really depends on what your shop computer is. If it is running WinXP, then you should be able to do it.

You don’t have to learn linux in order to use Linux CNC. Just follow their install instructions (you must have a good CDROM or else you will throw away your PC). Finish install, reboot and wait to show the desktop. Then you start the program.

If you wish to make milled PCBs, read this and go play with linuxcnc. The most important part in configuring LinuxCNC is to match its parameters with the instruction (and schematic) manual of your CNC: pinouts of the LPT port (what does each pin do? Which proximity sensor goes where?

How many steps per milimeter has each axis motor? See the CNC manual).

Save your configuration as “My Mill” or whatever. I am running my CNC – High-Z S/1000T without proximity sensors enabled and without automatic on/off control of the spindle. I adjust everything manually like in the Pleistocene era of the CNCs: X and Y homed to zero after I move the tool using just my eyes and a strong flash light as a reference. The Z axis I calibrate by lowering the step motor speed to 12mm/minute, and use a small piece of newspaper between the milling tool and the PCB surface.

When the piece of newspaper sheet can barely move, then the tool is ready to work. I use CadSoft Eagle with its “run pcb-gcode-setup” command.

There I set the milling depth to be -0.075mm and the maximum Z-down also to -0.075mm. The rest of the adjustments are the tool size (usually 0.1mm for SMD parts), maximum speed on all three axes and that would be all. Hi guys, I have been reading all of your posts and am grateful for all the info.

I don’t have any equipment yet but am looking at getting a small desktop type router or mill. I can buy different machines ready to go without the controller and software.

For someone looking at doing this as a hobby, should I go with Mach 3? I don’t really understand how LinuxCNC would work if it is not a program. Or maybe I just missed that part completely.

I looked at the Oliver Intellicarve 1013. That’s what I would like to do. I just think I can build or buy a bigger machine and add the controller and software. What do I need for software, controller and machine?