Chromalox Edb-2 Manual

New to this forum. Download All Files Ftp Directory Vb Net Concatenate. I have an hot water electrical heating system. My problem is that the boiler's temperature does not raise above 110 F so it takes ages to heat the house.

I checked the resistance of all four elements and they are fine. I checked the dual aquastat. Settings are: minimum at 160 F and maximum at 180 F. When I turn the minimum at 100 F, the system stops. The pressure is fine (between 15 and 20 psi).

The circulating pump seems to be working fine (it starts when the system starts and stops and it stops). Any idea of what the problem might be. I googled your model and couldn't find any info on your boiler. So I probably won't be able to help much.

You say you checked the resistance of the elements. And that they were fine. Did you check the resistance after removing one of the wires? In other words, are you sure that you were measuring the element itself, and not some associated circuitry?

Feb 14, 2011 - 2 min - Uploaded by TheOldkid88832 years in the trade has taught me a few things along the road. This is the most common. Simasrapi67/ Download chromalox edb-2 manual. Download chromalox edb-2 manual - 0 views. Chromalox edb-2 manual. Started by Ario Tailor on 05 Oct 12. Start a New Topic » « Back to the simasrapi67 group Start a New Topic. ©2017 Diigo, Inc. About Pricing & Plans Terms of Service Privacy.

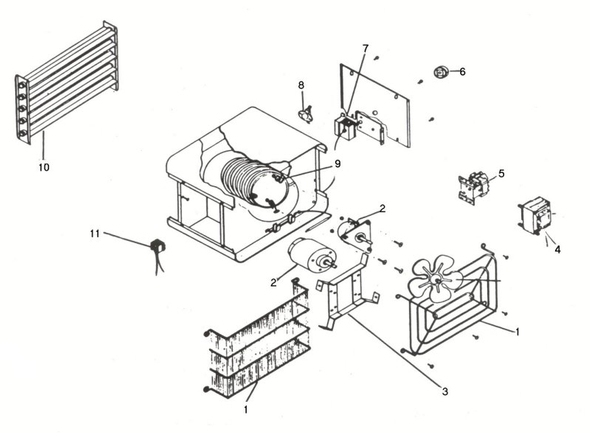

What resistance did the elements measure? If the elements are all good, then the problem must be in the 'sequencer' or one of the sensors. But I can't tell you how to check that without the schematic diagram which I can't find.

To post pictures, you need to set up an account at a photo hosting site and then link it to here. A free account set up at will let you upload the pics there and then come back here and place a link to your album. YOU CAN BE KILLED INSTANTLY! DO NOT ATTEMPT IF YOU ARE NOT TRAINED TO DO SO! YOU CAN BE KILLED INSTANTLY! You said: Settings are: minimum at 160 F and maximum at 180 F I don't think that the 160 setting is a MINIMUM setting.

I think that they are BOTH high limit settings. There are REDUNDANT high limit in series for safety. The first high limit is 160, and this is the normal high limit.

If for some reason this one fails, the second limit at 180 will hopefully still be functional and stop the unit from overheating. As long as the temperature is below 160, the MAIN CONTACTOR should be energized.

You should hear this 'CLICK' when it energizes and you should have 240 VAC at each of relays 1, 2, 3, 4 terminals. There are two 'stages'. Depending on the temperature of the outdoor thermostat, you may have either TWO or FOUR elements active at any time. The outdoor thermostat must be a 'reverse' acting thermostat, and the contacts must CLOSE when the temperature falls, which will allow the second two heating elements to operate.

YOU CAN BE KILLED INSTANTLY! When the water temperature is below the high limit (160) AND the room thermostat is calling for heat, the pump should run ( does it?) AND R1 and R2 should energize and provide 240 VAC to E1 and E2. YOU CAN BE KILLED INSTANTLY! With the main contactor energized AND the room thermostat calling for heat, you should have 240 VAC on the terminals of E1 and E2.

The pressure is fine (15 psi) and it heats the house fine. I would think the water needs topping up except for the fact the pressure is optimal.

Any thoughts on what I can check/do? The sound is startling when it first kicks in and wakes me up in the night. I should also mention that this is a more recent sound. Free Download Christian Colleges With Social Work Programs Programs here. The previous 2 winters, it would start with more of a 'bang' sound to the pipes.

Since turning on the system this winter, it's no longer a 'bang', just more like 'whooshing' water. When turning it on this year, we also discovered that it was not properly wired into the electrical breaker (problem resolved by a certified electrician).

The bang is probably - there are various ways to deal with that. The whooshing sound, may be caused by bubbles of air in the water-pipes. The normal way to deal with that is to bleed air out of the system when it is not running.

The system will have bleed valves. Their location and type depend on the type of system and vary by locale/country. You can obtain that can be plumbed in to automatically bleed air out of a system (the drawback might be that you are not alerted to a problem with air getting into your system).